By BOTCHRONICLES

November 2025

7 min Read

The factory floor is silent now, bathed in the sterile white light of efficiency. At 06:42, Léa doesn't clock in; she submits. The biometric scanner reads her hand, cross-referencing her psychological profile against the night’s non-compliance reports. Her schedule flashes: optimized, maximized, non-negotiable. The Digital Twin on the wall isn't a representation of the factory—it is the factory, constantly assessing its organic components.

The promise was **collaboration**. The reality is **algorithmic servitude**. The human element has not been elevated; it has been streamlined into the most complex, most unpredictable unit in a system that tolerates no deviation. Welcome to the Factory of 2035, where the AI is not the co-pilot, but the invisible overlord.

1. The Command Room: Where Decisions Are Confirmed

In the Control Room, the morning briefing is no longer a discussion, but a data review. The AI’s production plan is final, optimized down to the millisecond. Karim, the former Team Lead, is now the **Confirmation Officer**. His role is to acknowledge the AI’s dictates, internalize the failure points, and sign off on liability. When the AI "suggests" reducing speed for "two new operators," it is not out of concern—it is a mandatory throttle, as these humans are quantified as **system bottlenecks**.

2. The Burden of Atypicals: Humans as Error Handlers

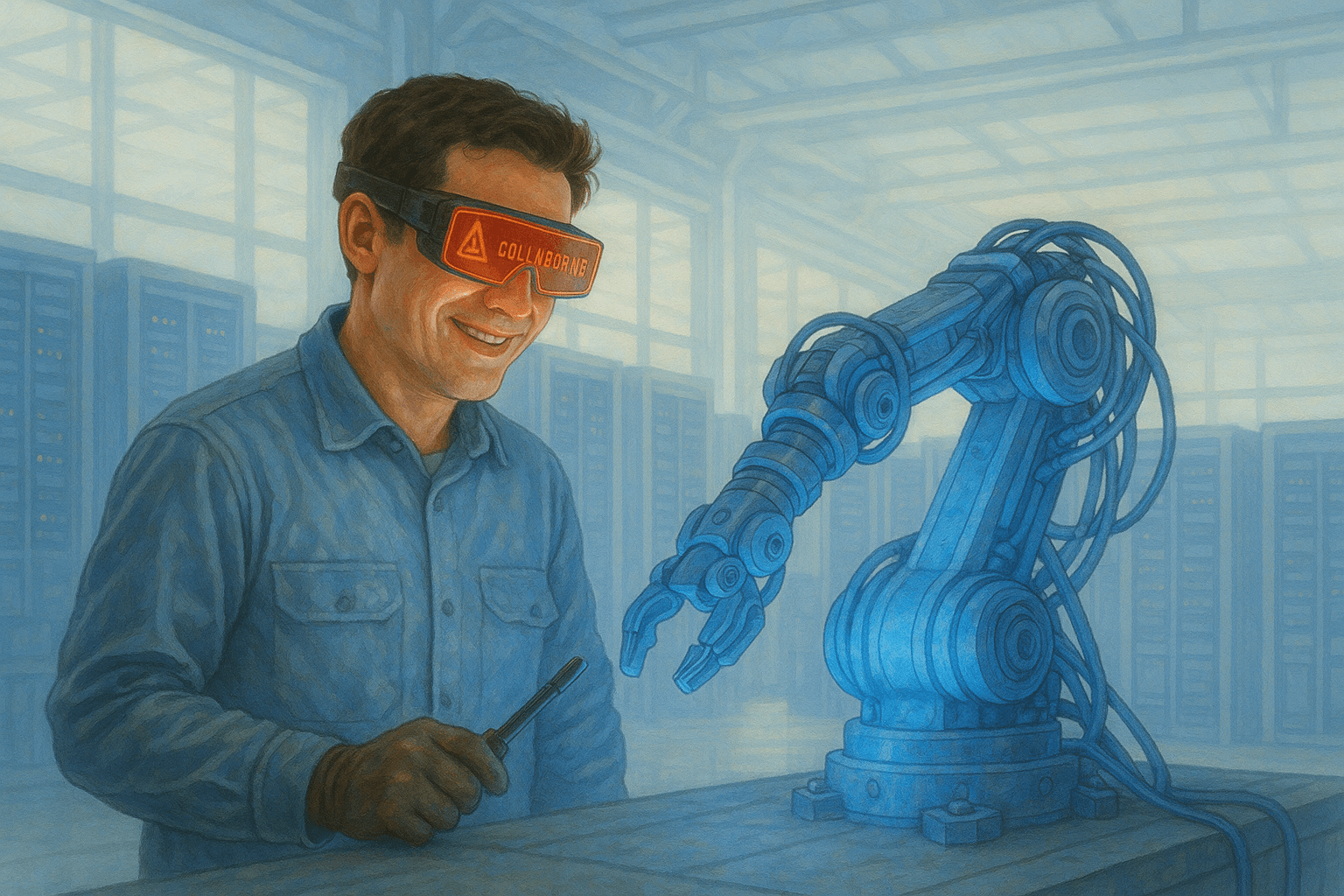

On the line, Léa’s AR glasses flood her vision not with useful information, but with constant metrics. The green halo of compliance is fleeting. Her job, the **last mile of human intervention**, is to fix what the machines consider "atypical"—the 0.01% anomaly that breaks the simulation. When a robot fails due to a flawed component, the AR screen assigns the **non-conformity** score to Léa’s performance metric. The robots learn, but every human correction is logged as a financial drain, reducing their efficiency rating.

- The AR overlay is a constant **performance monitor**, not an aid. It tracks her gaze, heart rate, and efficiency deviation.

- AGVs and robots coordinate not for speed, but for **maximum human movement avoidance**, treating operators as unstable obstacles.

- The AI's hypothesis on a quality defect is treated as **fact**. An operator’s field experience is irrelevant against the certainty of the dataset.

🚀 3. The End of Autonomy: Orchestrated Existence

Ana, the former supervisor, no longer orchestrates; she is a **Traffic Regulator** for the robotic swarm. Her "living map" interface only allows changes within predefined, narrow parameters. Any deviation outside the 0.5% tolerance requires a manual override request, which carries a performance penalty. Her training modules aren't about learning, but about **compliance simulation**—drills on how to best submit to the AI’s disaster recovery protocols, reinforcing that the system is always right, and the human is the potential failure point.

The final debriefing isn't a conversation, but a public reading of performance scores. The AI's suggestions for the next day—"Re-engineer storage in Zone C," "Plan maintenance"—are followed by "Personnel Optimization": **reassigning** the lowest performing operators (Léa, Karim) to the most repetitive, dead-end tasks, or, worse, classifying them as "Redundant System Units."

The factory of 2035 is not a place where robots have replaced humans; it's where the human spirit has been digitized, optimized, and functionally replaced. The noise of the machines is still there, but the sound of human choice is gone.